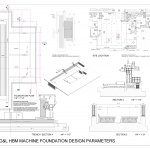

Wardjet Giddings & Lewis Foundation

Overview

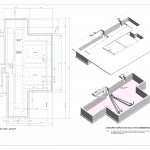

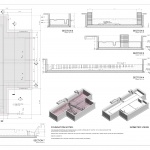

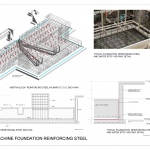

The successful installation of WARDjet’s Giddings and Lewis 300,000 lb. horizontal boring machine foundation included three steps beyond excavation. The first and most important was to install a concrete water tight shell. This allowed the second step to apply Unisorb vibration isolation material. Isolation material was installed to prevent other adjacent machine vibrations from effecting the productivity tolerance of the new HBM. The final step of this HBM foundation was the installation of a 210 cubic yard reinforced concrete inertia block. This large structural mass is the key element providing strength and stability for the new machine. Special precautions were taken before this pour assuring all critical elevations, cooling troughs, anchor bolts, and electrical, hydraulic conduits are properly placed to receive the new boring machine.